Making The Most Of Efficiency: Commercial Refrigeration Repair Work Techniques for Cost-Effective Solutions

Assessing Refrigeration System Efficiency

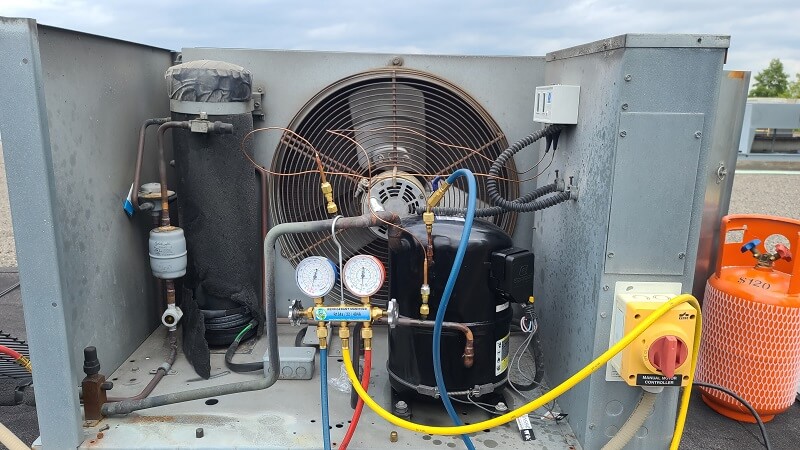

To effectively review the efficiency of a commercial refrigeration system, it is necessary to conduct comprehensive analyses of its vital parts and functional criteria. The primary step in evaluating system efficiency is analyzing the capability of the compressor. The compressor plays an essential role in keeping the desired temperature within the refrigeration unit. Problems with the compressor can result in insufficient cooling, temperature fluctuations, and enhanced power consumption. Carrying out normal evaluations and performance tests on the compressor can aid determine potential issues early and avoid expensive failures.

Keeping an eye on cooling agent levels and stress is likewise essential in examining system efficiency. Reduced refrigerant degrees or abnormal pressures can suggest leaks or malfunctioning elements that require immediate interest to prevent system failures and expensive fixings. By systematically examining these functional parameters and crucial components, organizations can ensure their industrial refrigeration systems run at peak efficiency degrees, minimizing downtime and maximizing power performance.

Executing Preventative Upkeep Procedures

Assessing the efficiency of an industrial refrigeration system supplies valuable insights that can notify the application of preventative maintenance measures vital for maintaining ideal capability and durability. By establishing a regular maintenance timetable, refrigeration systems can run effectively, reducing power consumption and minimizing the threat of unforeseen break downs. Ultimately, spending in preventative upkeep procedures is an economical technique that helps organizations stay clear of costly repair work and downtime, ensuring continual and trustworthy refrigeration system efficiency.

Identifying Common Refrigeration Issues

One of the crucial elements in keeping industrial refrigeration systems is quickly identifying common problems that might develop during their procedure. Additionally, damaged gaskets on doors, resulting in air leaks, can create the refrigeration system to function more challenging to maintain the desired temperature level. By promptly determining and addressing these typical refrigeration concerns, businesses can make certain the reliable procedure of their systems and lessen expensive repair services.

Using Energy-Efficient Fixing Techniques

When considering industrial refrigeration fixing, carrying out energy-efficient methods is vital to maximizing the system's efficiency and lowering operational prices. One of the vital methods in accomplishing energy performance is ensuring that the refrigeration system is effectively preserved. Normal upkeep, such as cleaning up condenser coils, looking for cooling agent leakages, and calibrating temperature settings, can dramatically improve energy performance.

An additional energy-efficient repair work strategy is updating to high-efficiency components - commercial refrigeration repair. By replacing older, much less discover here effective components with energy-efficient choices, such as ECM follower motors or LED lighting, businesses can lower power consumption and lower utility costs. Furthermore, installing programmable thermostats and energy administration systems can assist manage temperature levels more successfully, preventing unnecessary energy usage

Moreover, optimizing the system's insulation and securing any kind of leaks can additionally contribute to power cost savings. Appropriate insulation helps keep regular temperature levels within the refrigeration device, lowering the workload on the system and enhancing overall effectiveness. By integrating these energy-efficient repair techniques, businesses can not only decrease their environmental influence however likewise accomplish long-lasting cost savings.

Optimizing Refrigeration System Life Expectancy

To guarantee the durability and optimal performance of business refrigeration systems, preserving energy-efficient repair work methods is necessary, with an emphasis currently moving towards optimizing the refrigeration system lifespan. Maximizing the life-span of a refrigeration system entails positive maintenance, timely repair services, and adherence to manufacturer standards. Routine assessments to discover potential concerns before they escalate can dramatically prolong the system's lifespan (Toronto commercial Get More Information refrigerator repair). Applying a precautionary upkeep routine that consists of tasks such as cleansing coils, examining refrigerant levels, and examining insulation can aid determine problems early on and protect against costly failures.

Furthermore, informing team on proper system operation and maintenance techniques can contribute to the long life of the tools. Training employees to report any type of uncommon noises, leaks, or modifications in performance can assist in capturing issues in their first stages. Furthermore, purchasing premium components and parts during repair work and replacements can improve the durability of the refrigeration system. By prioritizing positive upkeep and making use of quality components, businesses can optimize the life-span of their commercial refrigeration systems, ultimately reducing downtime and operational prices.

Conclusion

Finally, by routinely examining refrigeration system efficiency, executing preventative upkeep procedures, recognizing common refrigeration problems, using energy-efficient fixing techniques, and maximizing the system's lifespan, services can make the most of effectiveness and lower prices connected with business refrigeration repair work. These economical options aid to ensure that refrigeration systems operate at peak efficiency, inevitably bring about increased productivity and success for companies over time.

When taking into consideration industrial refrigeration repair service, implementing energy-efficient strategies is paramount to enhancing the system's efficiency and minimizing functional prices.To ensure the longevity and ideal efficiency of industrial refrigeration systems, keeping energy-efficient fixing techniques is essential, with an emphasis now shifting towards optimizing the refrigeration system life-span. Maximizing the life-span of a refrigeration system includes positive upkeep, timely repair work, and adherence to maker standards.